Wide Body Blobeye Wagon....

#34

Thread Starter

Former Sponsor

iTrader: (24)

Joined: Jan 2009

Posts: 1,364

Likes: 0

From: Hyde Manchester

Got the 1/4 panels to nearly the right shape ,now a case of a lot of smoothing out and getting covered in filler dust

,now a case of a lot of smoothing out and getting covered in filler dust

This pic shows how wide kit is from standard, over 2"" per side

Mark @ HTAutos

,now a case of a lot of smoothing out and getting covered in filler dust

,now a case of a lot of smoothing out and getting covered in filler dust

This pic shows how wide kit is from standard, over 2"" per side

Mark @ HTAutos

#38

Ive done this kind of work before in the body shop and its very rewarding making custom stuff, I like the Question of how do you make them look the same both sides, Il give you the real answer, time and effort and a good eye are all correct but the main thing is if you can find me a person who can look at both sides of the car at the same time to tell you they are out then he must have a very wide head lol.

GO GO GADGET EYES !!!!!!!!!!!!

GO GO GADGET EYES !!!!!!!!!!!!

Last edited by JAutos; 10 February 2011 at 08:39 PM.

#43

Thread Starter

Former Sponsor

iTrader: (24)

Joined: Jan 2009

Posts: 1,364

Likes: 0

From: Hyde Manchester

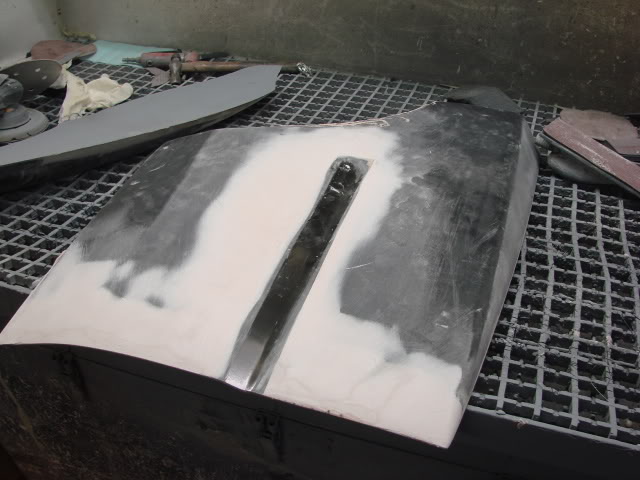

Bodyline on the kit door was not defined enough, so we cut it out and added another one,,,,,,,,,,,,

Back of kit nearly complete. This is a mirror image of the panel to be fitted to, so very easy to select position, and very easy to bond on.

Mark @ HTAutos

Back of kit nearly complete. This is a mirror image of the panel to be fitted to, so very easy to select position, and very easy to bond on.

Mark @ HTAutos

#48

Ive done this kind of work before in the body shop and its very rewarding making custom stuff, I like the Question of how do you make them look the same both sides, Il give you the real answer, time and effort and a good eye are all correct but the main thing is if you can find me a person who can look at both sides of the car at the same time to tell you they are out then he must have a very wide head lol.

GO GO GADGET EYES !!!!!!!!!!!!

GO GO GADGET EYES !!!!!!!!!!!!

anyway looks great, the bug eye hatch always looked a bit weedy without the wide arches of the saloon

#52

Thread Starter

Former Sponsor

iTrader: (24)

Joined: Jan 2009

Posts: 1,364

Likes: 0

From: Hyde Manchester

Should find some pics here; http://www.htautos.co.uk/7.html?frm_...data1_type=all

Cheers,

Mark @ HTAutos

#53

Thread Starter

Former Sponsor

iTrader: (24)

Joined: Jan 2009

Posts: 1,364

Likes: 0

From: Hyde Manchester

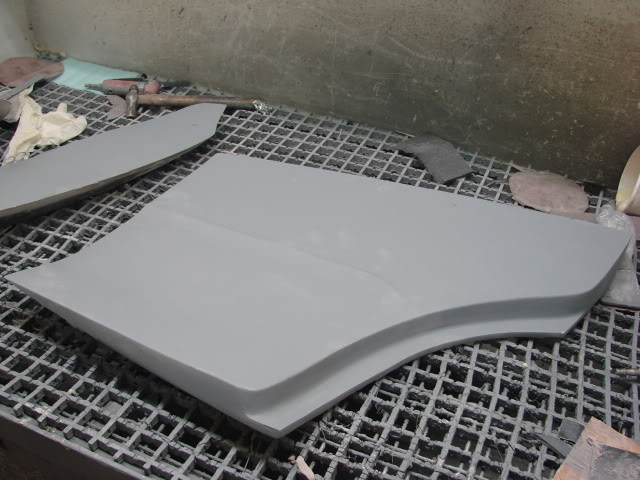

Panels now moulded

Next to cut arches to allow for wider wheels;

We cut throught outer arch, then pull up inner arch and weld together....

We then seal the welded joint, and prepare surfaces for bonding on panels............

Apply PU adhesive sealer to rear of panels...........

Bond on panels and hold in place with tape...........

Leave for 24hrs now

Mark @ HTAutos.

Next to cut arches to allow for wider wheels;

We cut throught outer arch, then pull up inner arch and weld together....

We then seal the welded joint, and prepare surfaces for bonding on panels............

Apply PU adhesive sealer to rear of panels...........

Bond on panels and hold in place with tape...........

Leave for 24hrs now

Mark @ HTAutos.

#59

Looks schweet.

That petrol flap looks wrong though, as does the rear bumper to arch join. Needs to be altered to like the side profile of a saloon bumper imo!

That petrol flap looks wrong though, as does the rear bumper to arch join. Needs to be altered to like the side profile of a saloon bumper imo!

Last edited by BLU; 25 February 2011 at 07:19 PM.

petrol flap will not open, as the hinge is different to the saloons

petrol flap will not open, as the hinge is different to the saloons . Brain gone dead now (its Sunday), have another look tomorrow

. Brain gone dead now (its Sunday), have another look tomorrow