AVCS Cams not lifting

#1

Hi guys, I am new here, from Singapore. My ride is a MY07 Hawkeye 4EAT WRX, which is running the JDM EJ20 engine.

Recently, I had it rebuilt with the following:

Mahle 8.0:1 92.5mm stroker pistons

Manley H-Beam conrods

ACL Race bearings

STI Crankshaft

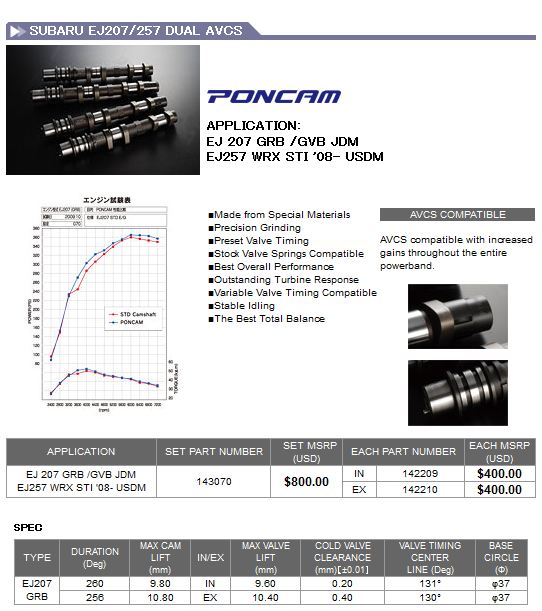

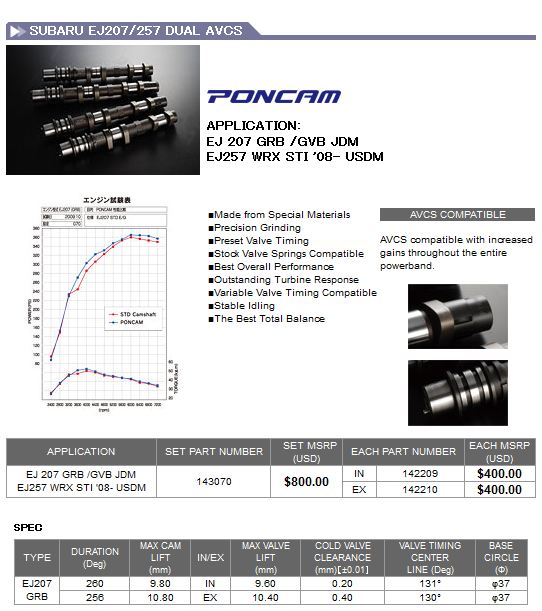

Tomei Procam 260 In/264 Ex

Subaru 12mm Oil Pump

GSC Valves

GSC Single Valve Spring Set with Titanium Retainers

DeatschWerks 750cc Fuel Injectors

I also upgraded by 16g to a Kamak TD05H-20GTX and had my TGV deleted with phenolic spacers added. OEM overhaul gaskets kit was used.

While having it tuned (after run-in), my tuner told me the cams ain't lifting. He showed me the datalog and I see figures of 3 deg across a range, I believe that was referring to AVCS.

So, I had it checked out at my workshop with a OBD scanner and discovered that both side's VVT timing were not in sync, RH will not go past 3 deg while LH is 6-7. Further checking, found out the RH cam gear is toast, got it replaced and now both sides are at 6-7 deg at idle. Seems rosy to me, took it for a test drive with the OBD scanner still plugged in, rev it between 4000-5000 rpm, but the VVT timing would only get to 12 deg max.

Is that right? My tuner was adamant that at that rev range, it should be in the 20s range. What could be wrong? Am I looking at the wrong values?

My next course of action was to have the OCVs checked out, it actuated ok. Put it back, still run the same. Replace with another set of OCVs, same. The only thing I am left to do is to remove the filters from the banjo bolts. Would that cause what I am experiencing?

edit: There are no CEL and I am also having intermittent sound at the RH at low rpms (1500-2000) which sounds like spitting into a spittoon and slight hesitation, which would go away after stepping on more gas...

Recently, I had it rebuilt with the following:

Mahle 8.0:1 92.5mm stroker pistons

Manley H-Beam conrods

ACL Race bearings

STI Crankshaft

Tomei Procam 260 In/264 Ex

Subaru 12mm Oil Pump

GSC Valves

GSC Single Valve Spring Set with Titanium Retainers

DeatschWerks 750cc Fuel Injectors

I also upgraded by 16g to a Kamak TD05H-20GTX and had my TGV deleted with phenolic spacers added. OEM overhaul gaskets kit was used.

While having it tuned (after run-in), my tuner told me the cams ain't lifting. He showed me the datalog and I see figures of 3 deg across a range, I believe that was referring to AVCS.

So, I had it checked out at my workshop with a OBD scanner and discovered that both side's VVT timing were not in sync, RH will not go past 3 deg while LH is 6-7. Further checking, found out the RH cam gear is toast, got it replaced and now both sides are at 6-7 deg at idle. Seems rosy to me, took it for a test drive with the OBD scanner still plugged in, rev it between 4000-5000 rpm, but the VVT timing would only get to 12 deg max.

Is that right? My tuner was adamant that at that rev range, it should be in the 20s range. What could be wrong? Am I looking at the wrong values?

My next course of action was to have the OCVs checked out, it actuated ok. Put it back, still run the same. Replace with another set of OCVs, same. The only thing I am left to do is to remove the filters from the banjo bolts. Would that cause what I am experiencing?

edit: There are no CEL and I am also having intermittent sound at the RH at low rpms (1500-2000) which sounds like spitting into a spittoon and slight hesitation, which would go away after stepping on more gas...

#2

Hi there

Not sure there,but when we are bought the our wagon,our AVCS solenoids hasn't been plugged to ECU,later on when we are went with 2.1L our AVCS has working as should

Did you check at least ECU ROM from this link

http://www.scoobypedia.co.uk/index.p...patibilityList

I would suggest at least log the AVCS with cheap OBD cable and Romraider SW,this should help you to diagnose the problem

Second bit,please have look on those threads

http://www.subaruforester.org/vbulle...se-help-93714/

http://forum.liberty.asn.au/viewtopic.php?f=18&t=20233

https://www.scoobynet.com/general-te...-bank-2-a.html

Yours mods can be the issue for the ECU as above thread and if you want have 100% control of AVCS then I would go with Syvecs,we are run Syvecs on the wagon and we are now running too Syvecs S6GP on the Honda Civic Type R

Thanks,Jura

Not sure there,but when we are bought the our wagon,our AVCS solenoids hasn't been plugged to ECU,later on when we are went with 2.1L our AVCS has working as should

Did you check at least ECU ROM from this link

http://www.scoobypedia.co.uk/index.p...patibilityList

I would suggest at least log the AVCS with cheap OBD cable and Romraider SW,this should help you to diagnose the problem

Second bit,please have look on those threads

http://www.subaruforester.org/vbulle...se-help-93714/

http://forum.liberty.asn.au/viewtopic.php?f=18&t=20233

https://www.scoobynet.com/general-te...-bank-2-a.html

Yours mods can be the issue for the ECU as above thread and if you want have 100% control of AVCS then I would go with Syvecs,we are run Syvecs on the wagon and we are now running too Syvecs S6GP on the Honda Civic Type R

Thanks,Jura

#3

Hi there

Not sure there,but when we are bought the our wagon,our AVCS solenoids hasn't been plugged to ECU,later on when we are went with 2.1L our AVCS has working as should

Did you check at least ECU ROM from this link

http://www.scoobypedia.co.uk/index.p...patibilityList

Not sure there,but when we are bought the our wagon,our AVCS solenoids hasn't been plugged to ECU,later on when we are went with 2.1L our AVCS has working as should

Did you check at least ECU ROM from this link

http://www.scoobypedia.co.uk/index.p...patibilityList

Hmm... how are the AVCS solenoids plugged to ECU? If it's the connector on the solenoid, it's plugged in, as we cleaned and also swapped another. It's strange, both sides are in sync, just that the VVT advance does not go past 12 deg at 4000-5000 rpm.

I am going to remove the banjo filters next, I wonder if they would affect the AVCS to that extent, they are in there for 100k km already.

If they aren't, are there other things I should look out for?

#5

Hmm... how are the AVCS solenoids plugged to ECU? If it's the connector on the solenoid, it's plugged in, as we cleaned and also swapped another. It's strange, both sides are in sync, just that the VVT advance does not go past 12 deg at 4000-5000 rpm.

I am going to remove the banjo filters next, I wonder if they would affect the AVCS to that extent, they are in there for 100k km already.

If they aren't, are there other things I should look out for?

I am going to remove the banjo filters next, I wonder if they would affect the AVCS to that extent, they are in there for 100k km already.

If they aren't, are there other things I should look out for?

You are still running OE harness or did you use STI AVCS harness ?

Something like this

http://www.jti.uk.com/product/subaru-avcsvvt-loom/

http://www.iaperformance.com/product...oducts_id=3217

Without enabled AVCS or plugging them to the ECU,cams will run in retarded position

This should help there

http://bbs.22b.com/forums/showthread...WRX-AVCS-Query

I would speak with Tim@Jti.uk which would be able help you with the harness he will make for you harness if needs to be made

Thanks,Jura

Wagon is no longer,has been broken few months ago and really miss that wagon there

Now Syvecs can control 4EAT too and can control shifting points on the 4EAT too,they're made custom S6 for 4EAT or for cars with autoboxes

Wish I know I wouldn't never go with manual,with 4EAT and with this customization of the shifting points(4EAT in stock shifts too early or too late) you will have awesome combo

Agree Works Bell Paddle shifter is awesome bit of kit,we are been very pleased with this kit

You are have nice setup too and yours spec is good too there,should make nice numbers

You are still running stock 4EAT?

Thanks,Jura

#6

I would believe it is OE, never did anything to the harness, and the engine comes with AVCS originally (JDM). How do you tell if AVCS is enabled? Any signs or indicators?

My 4EAT is stock except for a high stall TC. Syvecs can control shifting points??? I thought that can only be done by the TCU? You got my attention there The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

My 4EAT is stock except for a high stall TC. Syvecs can control shifting points??? I thought that can only be done by the TCU? You got my attention there

The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

#7

I would believe it is OE, never did anything to the harness, and the engine comes with AVCS originally (JDM). How do you tell if AVCS is enabled? Any signs or indicators?

My 4EAT is stock except for a high stall TC. Syvecs can control shifting points??? I thought that can only be done by the TCU? You got my attention there The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

My 4EAT is stock except for a high stall TC. Syvecs can control shifting points??? I thought that can only be done by the TCU? You got my attention there

The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.

The problem is, the tuning part, I believe there is no one here that specialize in Syvecs and the closest dealer to me is in Malaysia.Not sure if yours AVCS are plugged,on our JDM WRX wagon we didn't have this plugged to ECU and as our engine builder said us,we are run them in retarded position

Please have look on this

http://forums.nasioc.com/forums/show....php?t=2439060

Are you running AVCS pulley set or you are running non AVCS cam gear?

Second bit I would check if yours timing belt is correctly fitted,mis-aligned timing belt can cause lots of issue and you are already running upgraded valvetrain

I would suggest OBD cable and use Romraider for logging the data

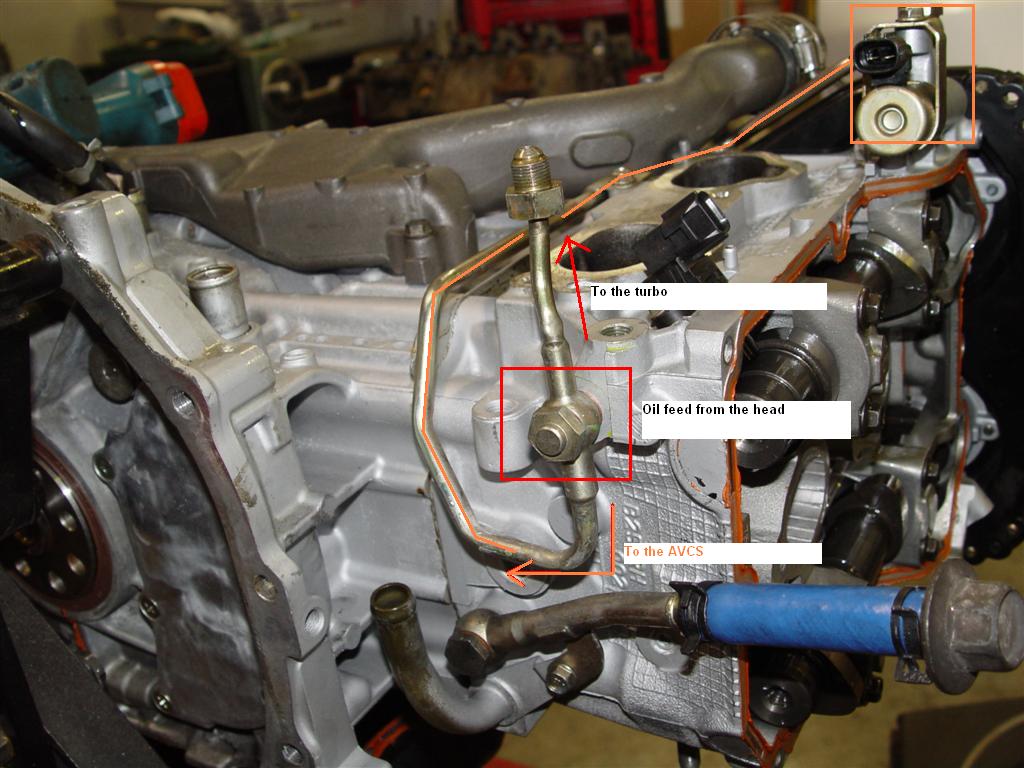

Here is how should looks yours AVCS oil feed etc.

Yes Syvecs can control the shifting points,I spoke with Charlie@Syvecs and he confirmed me this

https://www.facebook.com/video.php?v=767365603291038

I would speak with Jasper,he is located in Taiwan,but I think he travel a lot,maybe he will able to help you

I will PM you his email address,if you want

Thanks,Jura

Trending Topics

#8

#10

Are you running AVCS pulley set or you are running non AVCS cam gear?

Second bit I would check if yours timing belt is correctly fitted,mis-aligned timing belt can cause lots of issue and you are already running upgraded valvetrain

I would suggest OBD cable and use Romraider for logging the data

Here is how should looks yours AVCS oil feed etc.

Yes Syvecs can control the shifting points,I spoke with Charlie@Syvecs and he confirmed me this

https://www.facebook.com/video.php?v=767365603291038

I would speak with Jasper,he is located in Taiwan,but I think he travel a lot,maybe he will able to help you

I will PM you his email address,if you want

Thanks,Jura

Second bit I would check if yours timing belt is correctly fitted,mis-aligned timing belt can cause lots of issue and you are already running upgraded valvetrain

I would suggest OBD cable and use Romraider for logging the data

Here is how should looks yours AVCS oil feed etc.

Yes Syvecs can control the shifting points,I spoke with Charlie@Syvecs and he confirmed me this

https://www.facebook.com/video.php?v=767365603291038

I would speak with Jasper,he is located in Taiwan,but I think he travel a lot,maybe he will able to help you

I will PM you his email address,if you want

Thanks,Jura

I will take a look at the hard oil lines. I assume that it is enabled. I had it tuned before by the same tuner and he did not feedback to me about the AVCS/VVT timings until he did the retune for the rebuilt engine. And yes, it is using AVCS cam gears. My tuner is quite insistent that the timing should be 20+ deg at 4000-5000 rpm. My mech told me the timing belt is correctly fitted.

Sure, do please pm me his contact

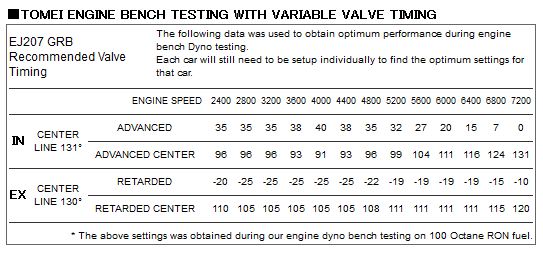

Some info here on the Tomei poncam on AVCS

http://www.tomeiusa.com/news/Report-EJ25-V1.html

http://www.tomeiusa.com/news/Report-EJ25-V1.html

#11

Yes I know

It was document relating to structure & research on both EJ207 & EJ255 /7

Using the poncam

Wich by the way has very little lift

But since your not using the poncam

Disregard this

It was document relating to structure & research on both EJ207 & EJ255 /7

Using the poncam

Wich by the way has very little lift

But since your not using the poncam

Disregard this

#13

#14

Are the AVCS pulleys located on the camshaft locating pin correctly - have seen misalignment on several rebuilt engines in the past causing the AVCS not to work.

A sure sign is when you remove the pulley, the locating hole in the pulley has been elongated.

The screen filters in the banjo bolts can get clogged with debris from a previous engine failure causing a low flow of oil to the OCV.

Have even seen stray sealant and a collapsed screen filter stuck in the OCV shuttle valve causing it not to operate.

Mick

A sure sign is when you remove the pulley, the locating hole in the pulley has been elongated.

The screen filters in the banjo bolts can get clogged with debris from a previous engine failure causing a low flow of oil to the OCV.

Have even seen stray sealant and a collapsed screen filter stuck in the OCV shuttle valve causing it not to operate.

Mick

#15

Are the AVCS pulleys located on the camshaft locating pin correctly - have seen misalignment on several rebuilt engines in the past causing the AVCS not to work.

A sure sign is when you remove the pulley, the locating hole in the pulley has been elongated.

The screen filters in the banjo bolts can get clogged with debris from a previous engine failure causing a low flow of oil to the OCV.

Have even seen stray sealant and a collapsed screen filter stuck in the OCV shuttle valve causing it not to operate.

Mick

A sure sign is when you remove the pulley, the locating hole in the pulley has been elongated.

The screen filters in the banjo bolts can get clogged with debris from a previous engine failure causing a low flow of oil to the OCV.

Have even seen stray sealant and a collapsed screen filter stuck in the OCV shuttle valve causing it not to operate.

Mick

How does the locating pin on the pulley look like?

#16

I think there is picture how it looks

http://forums.nasioc.com/forums/show....php?t=2175750

Thanks,Jura

http://forums.nasioc.com/forums/show....php?t=2175750

Thanks,Jura

#17

I will have the pins checked out too, how do you see if it is located incorrectly (if I do not see signs of elongation like in the picture)? I think in that nasioc thread with the pin picture you posted, Irv Weissmanhowerton have a situation of AVCS not advancing as it should, seems like it is similar to my case (Just that he is using Kelford cams), I see that no one replied to that...

Oh, another thing I am curious...

That is the "Valve Timing Center Line" under Spec. What is that? Does that mean something have to be adjusted differently from OE?

Oh, another thing I am curious...

That is the "Valve Timing Center Line" under Spec. What is that? Does that mean something have to be adjusted differently from OE?

#18

As you have aftermarket cams fitted, I would presume the exhausts were dialled in timing wise, so what are your static timing figures, including the inlets ?, that will tell you if the inlets are on the dowels correctly, & if they were not dialled in your wasting your time with aftermarket cams to get the best from them.

Jura,

Your picture looks very much like a incorrectly fitted pulley to cam, you can see its damaged, & clearly see the misaligned oil feeds, not a good example of what it should look like.

Jura,

Your picture looks very much like a incorrectly fitted pulley to cam, you can see its damaged, & clearly see the misaligned oil feeds, not a good example of what it should look like.

Last edited by MOTORS S GT; 23 October 2014 at 07:55 AM.

#19

As you have aftermarket cams fitted, I would presume the exhausts were dialled in timing wise, so what are your static timing figures, including the inlets ?, that will tell you if the inlets are on the dowels correctly, & if they were not dialled in your wasting your time with aftermarket cams to get the best from them.

Do you mean dialing in reference to the centerline listed in the cam specs? I don't know the specifics, but I will ask my mech about that just in case.

#21

#22

Would not following the spec centerline cause problems to AVCS? Or just that I can't the full potential of the cams. My mech did the timing belt like OE. Point to note that AVCS are in sync, just that the max timing it goes is 12*, idle at 6-7*.

#23

If you don't know what the cams are timed in at static, saying plus this & plus that is a bit meaningless, why people build engines & with non oe cams & just line up the marks is pointless, you are probably throwing good power away after spending out on cams that require a specific centreline to get whats claimed power wise, & there is probably several degrees difference between right & left cams, especially with skimmed blocks, heads & gasket tolerences.

#24

If you don't know what the cams are timed in at static, saying plus this & plus that is a bit meaningless, why people build engines & with non oe cams & just line up the marks is pointless, you are probably throwing good power away after spending out on cams that require a specific centreline to get whats claimed power wise, & there is probably several degrees difference between right & left cams, especially with skimmed blocks, heads & gasket tolerences.

I get what you mean, but would that cause AVCS to not function as it should. Or, are you implying that whatever reading I get is pointless if I do not get the specs in order first?

#25

It will not stop the avc's from functioning, whatever the timing is static, but what I am trying to point out is, is the avc's pulley actually zeroing, as in the static locked position when fitted, this you will not know unless it was measured on the build, normally the centreline on oe cams is 127 to 131 deg's in the locked position, if its not that its either not correctly fitted on its dowel, the pulley is not returning to its locked position, or the cams made wrong.

I said its pointless just putting aftermarket cams in untimed, not pointless in your avc's running figures, but as I mentioned, you may well have several degrees difference between r/h & l/h, if say the r/h is static at 127 deg, & the l/h is 131deg, running you have a 4 deg difference, if while running the ecu is then trying even up the positioning & is trying to run both cams evenly with a 4 deg offset to start with, this also assuming the trigger slots are correct on the cams.

I said its pointless just putting aftermarket cams in untimed, not pointless in your avc's running figures, but as I mentioned, you may well have several degrees difference between r/h & l/h, if say the r/h is static at 127 deg, & the l/h is 131deg, running you have a 4 deg difference, if while running the ecu is then trying even up the positioning & is trying to run both cams evenly with a 4 deg offset to start with, this also assuming the trigger slots are correct on the cams.

Last edited by MOTORS S GT; 23 October 2014 at 01:45 PM.

#27

By setting up a 360 deg protractor on the crank, removing both cam covers & measuring, engine will have to come out to do it correctly.

#28

Thought I shoudl close this off (for me).

Finally found the problem and the solution (which no one will like).

As it turned out, it had everythign to do with the cam timing in the exhaust side (where there is no AVCS). The cam base timing was WAY off. It is supposed to be aprox 113 degrees @ TDC (Top Dead Center) but one side fo rme was 126deg and the other side was 118 deg.

Essentially means that the overlap in the valves was too great and caused exhaust gas back into the intake causing the stumble and hesitation..

IT has nothing to do with the cams I used because they can not be changed and are always tested before being used. This problem is not there for the intake simply because AVCS adjust's it on the fly.

So we took the engine out (4th time for me haha) and open the heads, then had to buy a set of exhaust side adjustable JUN cam gears and dial the timing back to base 113 degrees.

Put everythign back together and what do u know.. PERFECT!!! The car has more torque and pull than it ever had exactly where the hesitation used to be..

I believe this was a major fault with the 06-07 single AVCS STI's and Subaru is to blame.. They introduced dual AVCS to fix this problem I beliebe. There is soooo many people with this problem in the US and I have since found about 4 people in Singapore also..

Finally found the problem and the solution (which no one will like).

As it turned out, it had everythign to do with the cam timing in the exhaust side (where there is no AVCS). The cam base timing was WAY off. It is supposed to be aprox 113 degrees @ TDC (Top Dead Center) but one side fo rme was 126deg and the other side was 118 deg.

Essentially means that the overlap in the valves was too great and caused exhaust gas back into the intake causing the stumble and hesitation..

IT has nothing to do with the cams I used because they can not be changed and are always tested before being used. This problem is not there for the intake simply because AVCS adjust's it on the fly.

So we took the engine out (4th time for me haha) and open the heads, then had to buy a set of exhaust side adjustable JUN cam gears and dial the timing back to base 113 degrees.

Put everythign back together and what do u know.. PERFECT!!! The car has more torque and pull than it ever had exactly where the hesitation used to be..

I believe this was a major fault with the 06-07 single AVCS STI's and Subaru is to blame.. They introduced dual AVCS to fix this problem I beliebe. There is soooo many people with this problem in the US and I have since found about 4 people in Singapore also..

I googled this out. Could this be the problem? Do I really need an aftermarket exhaust cam gear to adjust the timing?

#29

If you want to do it correctly, yes, that's why they make vernier pulleys there not for looks, but what do I know.

You could also check your timing on std pulleys, then alter the location as per grp n rally engines.

You could also check your timing on std pulleys, then alter the location as per grp n rally engines.

Last edited by MOTORS S GT; 23 October 2014 at 07:04 PM.

#30

I took this photo today to show a damaged AVCS Inlet pulley due to misalignment of the locating dowel on the camshaft.

The arrow shows the damaged locating hole on the AVCS pulley and you can see how it has distorted the oil hole to the right of it too.

As said above, its pointless to fit aftermarket cams without dialing them in to the MOP given on the data sheet supplied with the cams.

You can dial the exhaust cams in easily enough using the Grp N/Prodrive method with standard pulleys, but I prefer to slot the original pulley dowel hole to give you at least one tooth of adjustment to dial the cams in. This way also allows you to keep the locating dowel in the camshaft for peace of mind.

Set up to dial the cams in using Vernier pulleys on non AVCS heads

Mick

The arrow shows the damaged locating hole on the AVCS pulley and you can see how it has distorted the oil hole to the right of it too.

As said above, its pointless to fit aftermarket cams without dialing them in to the MOP given on the data sheet supplied with the cams.

You can dial the exhaust cams in easily enough using the Grp N/Prodrive method with standard pulleys, but I prefer to slot the original pulley dowel hole to give you at least one tooth of adjustment to dial the cams in. This way also allows you to keep the locating dowel in the camshaft for peace of mind.

Set up to dial the cams in using Vernier pulleys on non AVCS heads

Mick