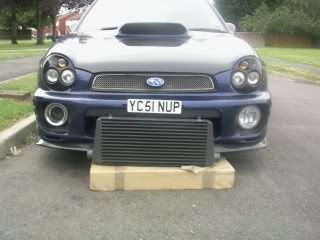

powder coating front mount

#1

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

Anyone done it? does the powder coating cling to the fins correctly. bout to have mine done and worried it wont set right

#2

Scooby Senior

iTrader: (3)

Join Date: Jun 2006

Location: Slowly rebuilding the kit of bits into a car...

Posts: 14,333

Likes: 0

Received 0 Likes

on

0 Posts

IIRC the powder is sprayed and coats evenly due to electrostatic attraction, and is then baked hard in an oven.

So long as your IC doesn't melt.... LOL !

You should be o.k.

All IMHO

DunxC

P.S, Thinks... mine needs to be colour coded black....

So long as your IC doesn't melt.... LOL !

You should be o.k.

All IMHO

DunxC

P.S, Thinks... mine needs to be colour coded black....

#4

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

pmsl. it was the bloke doing it that said that small electrical charges on the thin bits could repel the coating.

got a colour in mind mate and its not the norm

got a colour in mind mate and its not the norm

Trending Topics

#12

Standard powder coating techniques that leave a smooth surface will require 30-50microns.

There is a new technique which suspends the powder in water allowing a thinner coating to be applied, typically 3-5 microns, which will give a smooth finish.

But the coatings are normally either Polyester or Epoxy. Both are good insulators of heat.

So if your man is using the water borne powder system then you'll only lose some of your thermal efficiency.

If he's not then you'll lose lots of thermal efficiency.

Function over form for me not form over function. Thats all.

There is a new technique which suspends the powder in water allowing a thinner coating to be applied, typically 3-5 microns, which will give a smooth finish.

But the coatings are normally either Polyester or Epoxy. Both are good insulators of heat.

So if your man is using the water borne powder system then you'll only lose some of your thermal efficiency.

If he's not then you'll lose lots of thermal efficiency.

Function over form for me not form over function. Thats all.

#13

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

Standard powder coating techniques that leave a smooth surface will require 30-50microns.

There is a new technique which suspends the powder in water allowing a thinner coating to be applied, typically 3-5 microns, which will give a smooth finish.

But the coatings are normally either Polyester or Epoxy. Both are good insulators of heat.

So if your man is using the water borne powder system then you'll only lose some of your thermal efficiency.

If he's not then you'll lose lots of thermal efficiency.

Function over form for me not form over function. Thats all.

There is a new technique which suspends the powder in water allowing a thinner coating to be applied, typically 3-5 microns, which will give a smooth finish.

But the coatings are normally either Polyester or Epoxy. Both are good insulators of heat.

So if your man is using the water borne powder system then you'll only lose some of your thermal efficiency.

If he's not then you'll lose lots of thermal efficiency.

Function over form for me not form over function. Thats all.

from what ive read its not as thick as 50 microns and quoted 5 max so guessing this is technique being used.

as for losing effeciency, it will be minimum due to surface area plus water spray and location being a front mount gets all the air.

I'm after a stealth look to the car now and changing the colour is needed. i understand i will lose some but im not running a very high powered car to really notice.

but cheers for advice and i will check with bloke tomorrow to double check

#14

no probs.

I did also find out that paint can be upto 80microns thick for a really nice flat lustrous job.

Also make sure it's a polyester powder. Or at least, not epoxy. The epoxy coats fade in UV (outside daylight) and start to chalk up where the polyester ones don't.

Good luck with it anyway.

I did also find out that paint can be upto 80microns thick for a really nice flat lustrous job.

Also make sure it's a polyester powder. Or at least, not epoxy. The epoxy coats fade in UV (outside daylight) and start to chalk up where the polyester ones don't.

Good luck with it anyway.

#15

Scooby Regular

iTrader: (23)

Join Date: May 2006

Location: Rota Subzeros FOR sale!

Posts: 3,701

Likes: 0

Received 0 Likes

on

0 Posts

I'm getting the end tanks powdercoated on my FMIC and then just going to spray the fins with a light coating of black paint, that should be enough to keep it stealthy!

Have a look at the projects where the widebody Neils building, he just gave the FMIC a light coat HTHs

S!

Have a look at the projects where the widebody Neils building, he just gave the FMIC a light coat HTHs

S!

#17

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

well its in the workshop now getting done and hopefully pick it up tomorrow.

had a chat with the bloke and he was going to just spray it on but when voiced my concerns he will do it by floating in liquid. think its costing slightly more as its time consuming.

on the negative side though i couldnt get the colour i first wanted as it can only be sold in 5kg's and thats £120+vat+postage and he wouldnt buy it in so i would have to buy it all(this amount of powder can coat 200 intercoolers)

so ive gone for a dark charcoal with a metalic fleck in it.

hopefully fitting on tuesday so will post pics

had a chat with the bloke and he was going to just spray it on but when voiced my concerns he will do it by floating in liquid. think its costing slightly more as its time consuming.

on the negative side though i couldnt get the colour i first wanted as it can only be sold in 5kg's and thats £120+vat+postage and he wouldnt buy it in so i would have to buy it all(this amount of powder can coat 200 intercoolers)

so ive gone for a dark charcoal with a metalic fleck in it.

hopefully fitting on tuesday so will post pics

#22

Former Sponsor

iTrader: (48)

I get quite a lot of powder coating done but I would not powder coat the FMIC core because it will reduce the ability to dissipate heat. The Hybrid cores are anodised aluminium and have a degree of corrsoion protection but the potash on our roads (salt) during Winter is an extremely corrosive environment.

I guess it's a balance between appearance and performance and I hope it works out for you.

Do you have any means of measuring air charge temperatures?

I guess it's a balance between appearance and performance and I hope it works out for you.

Do you have any means of measuring air charge temperatures?

#23

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

no harvey but i'd be very interested in doing it.

how is the best way as ive not seen it done.

adapter arrived today as you promised mate.

thanks again

how is the best way as ive not seen it done.

adapter arrived today as you promised mate.

thanks again

#24

Former Sponsor

iTrader: (48)

I may have an air charge temperature guage here, if not I do expect a batch in shortly. I am measuring the ACT and ambient temps on the STi 3 Wagon with an STi 8 TMIC, the 95 WRX Wagon with a Hybrid GT FMIC and the STi 6 Wagon with APS FMIC. Temporarily I measured the ACT on the STi UK with O/E TMIC.

I guage the performance of the intercooler by the temperature over ambient with the probe at the throttlebody.

I guage the performance of the intercooler by the temperature over ambient with the probe at the throttlebody.

#25

Essex Area Moderator

iTrader: (7)

Harvey, the APS units are powdercoated from the factory inc the cores.

Mines been painted inc a matt finish laquer and there is no difference to my ACTs whatsoever.

Im using an RB motorsport gauge mounted in the charge pipe just before my throttle body. Shown here,

Mines been painted inc a matt finish laquer and there is no difference to my ACTs whatsoever.

Im using an RB motorsport gauge mounted in the charge pipe just before my throttle body. Shown here,

#26

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

Frayz what am i looking at there, cant see what your talking about.

i'd be interested in seeing the temps but i would have nothing to compare them to as i didnt have it on there when i had my sti8 topmount

i'd be interested in seeing the temps but i would have nothing to compare them to as i didnt have it on there when i had my sti8 topmount

#28

412/425 of forged love

Thread Starter

iTrader: (12)

Join Date: Jan 2008

Location: www.surreyscoobies.com

Posts: 4,238

Likes: 0

Received 0 Likes

on

0 Posts

got it now, tidy little job.

is it just a normal temp sender in there and normal gauge?

looks good and will be something i might look at in the future.

cheers

#30

Essex Area Moderator

iTrader: (7)

I can tell you for sure that my DR725 is powdercoated.

Read this article mate

Google Image Result for http://us1.webpublications.com.au/static/images/articles/i20/2072_2lo.jpg

I quote:

"The main purpose of the cleaner/dryer machine is to prepare the surface of the intercooler for powder coating. At the time of writing, APS has powder coating done by an outside company - but this may soon change. Powder coating is essential to protect the aluminium core and end-tanks from corrosion - especially in areas where salt is used to clear snow-covered roads. The intercooler can be specified with either black or silver powder coating."

Read this article mate

Google Image Result for http://us1.webpublications.com.au/static/images/articles/i20/2072_2lo.jpg

I quote:

"The main purpose of the cleaner/dryer machine is to prepare the surface of the intercooler for powder coating. At the time of writing, APS has powder coating done by an outside company - but this may soon change. Powder coating is essential to protect the aluminium core and end-tanks from corrosion - especially in areas where salt is used to clear snow-covered roads. The intercooler can be specified with either black or silver powder coating."